FOOD & BEVERAGE

Reduced fouling and scaling in the food & beverage industry

Chemical-free cleaning and prevention with zero process downtime

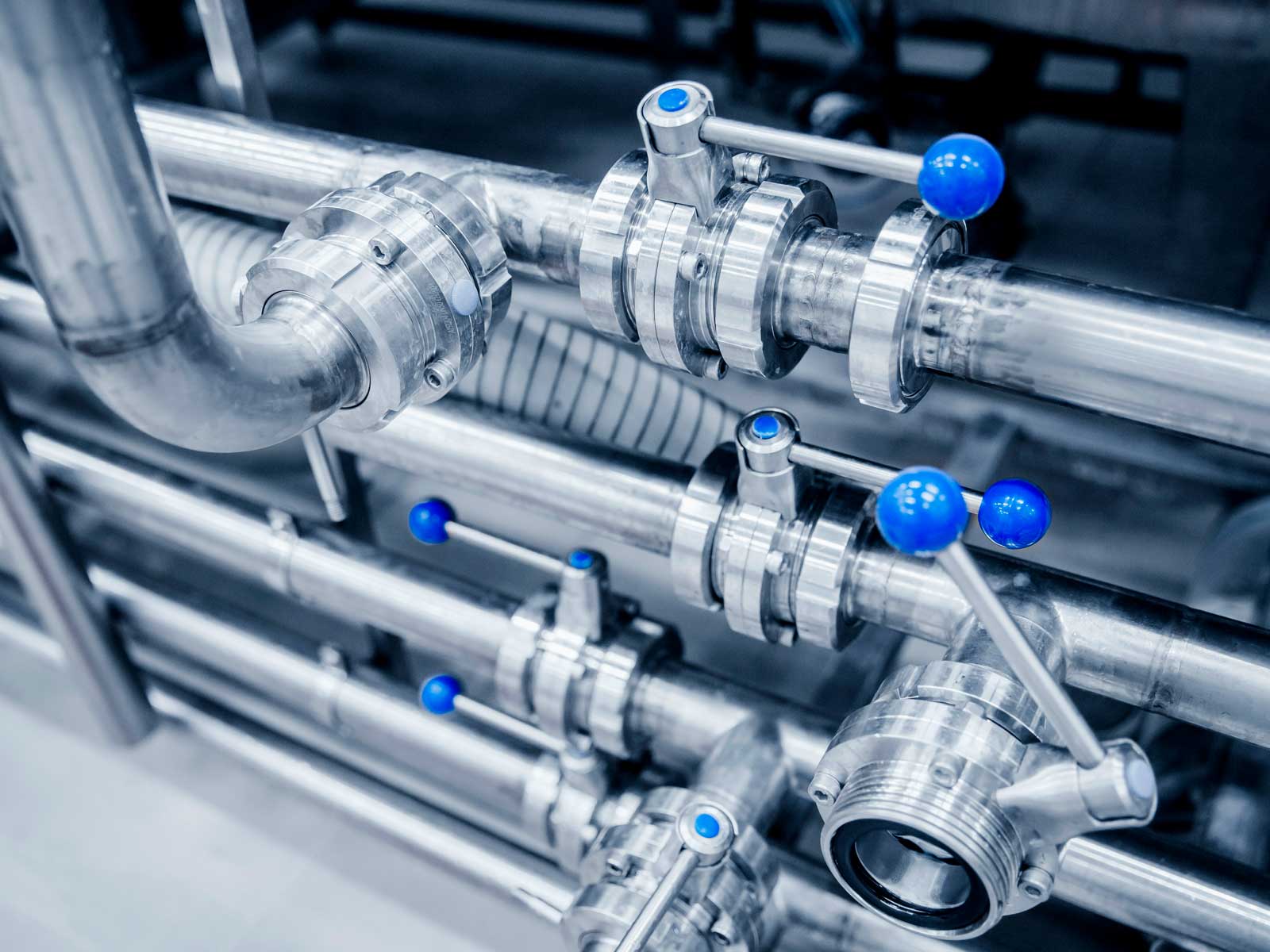

THE PROBLEM: CLEANLINESS IS EVERYTHING IN FOOD & BEVERAGE PRODUCTION

The food & beverage industry is a complex and diversified sector that is sub-divided into many types of activities. Food production has distinctive characteristics which distinguish it from other process industries, such as short batch-type production processes due to variable market demands and high requirements for quality and cleanliness.

Most of the processes consist of many different sub processes but almost all have a major one in common, Aseptic treatment. Cleaning is the key to most food industry processes. Achieving maximum hygienic performance is traditionally obtained via a combination of Clean-in-Place (CIP) and manual cleaning. These two methods have a high cost and production capacity is often reduced by lengthy washes.

THE BENEFITS OF ALTUM’S ZPD ULTRASONIC TECHNOLOGY IN FOOD & BEVERAGE PRODUCTION INCLUDE:

- Removes food soil like burnt-in sugar or proteins that CIP (Clean-in-Place) methods can’t, and protects your end products from contamination by these residues.

- Improves the mechanical effect of chemical cleaning, reaching places where the design does not allow easy access and washing is therefore poor

- Prevents clogging in sensitive places.

- Emulsifies fatty soils and formulas, allowing you to easily get rid of fat deposits in places where CIP/caustic can’t be used.

- Homogenizes products, thus making them and the equipment less prone to fouling.

- Has a mild disinfectant effect that combines with chemical disinfection to make it more efficient.

REFERENCES IN FOOD INDUSTRY